Your Hunch is Probably Correct

Let’s discuss operational problems. You have a problem with your Rescue Water Craft program. You aren’t sure what is right or wrong.

But you know things are not adding up sequentially and some things may not appear to be safe.

Nobody is listening to you when you make a comment regarding your observation and you may not be listening to this intuitive advice that is warning you.

What can you do?

You have three choices:

1. Identify the problems and probable cause and submit an inquiry on inspections and audit, write it down.

2. Say nothing; remain silent waiting for something to ‘blow’

3. Ask for help and assistance in identifying corrective measures. Work towards resolution as the spokesperson of what was identified, what needs to be corrected, how it can be achieved. Don’t stop.

Hopefully your leadership listens. If not write down and chronicle your concerns and protect yourself from hubris.

Maintain a diary of connective accounts of your concerns. Share them with the team. The issue is will you risk the negative feedback loop which can result in bullying and ‘we have always done it this way’, ‘don’t rock the boat’. You decide if you will become a safety warrior or not, it’s a dividing time.

The collapse of a program, a mishap or an injury is a 'signature'. It was written on a contract to provide health and safety practices in the maritime or water safety community. When you take a course, receive a qualified certification or join a team, your commitment (signature) is a contract.

The terms and conditions may be sparse or well defined. Too many programs work towards the status quo which is the lowest level of performance. They may have been presented far too many disciplines to manage, assigned not enough operational budget, unrealistic response capability by the public demands; and personnel who are not wholly committed to their signature placed on a contract. The links in the chain are all inter - dependent.

It’s a system. And the system is controlled by people. We fail and succeed, and mistakes are often repeated even though the lessons were already preserved. It can become a fatigue of generational losses. It will take a unique individual with leadership intuition and skill to ‘hold the line’ of safety.

It requires effort and perseverance against the bullies and naysayers. And there will be plenty of them.

When this collapse aka mishap occurs; it is unpredictable of the time of delivery, the location or the asset being used. It is a full spectrum of program management and efficiency. Not limited to personnel.

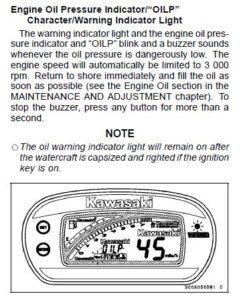

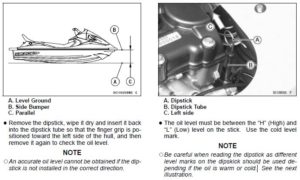

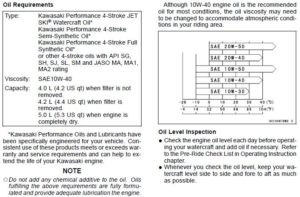

Hourly equipment maintenance schedules ignore, the probability of causation will lean more to past the recommended manufacturer’s schedules. Once you move past that required hourly maintenance best practice complications arise:

1. Costs for repairs

2. Injury

3. Accident

4. Loss of Asset

5. Loss of public service

6. Liability

7. Negligence and assigned levels to responsible parties/persons

We cannot predict when it will happen, but we can rely on the unpredictability that these things occur when its least needed and causes chaos.

Your job is to ensure order is in place. This requires budget, time, manpower, tools/supplies and knowledge.

Losing sight of the simplest of things such as the hourly maintenance schedule can cost a teammate their productivity, income, reputation or life. This expands to the public expectation of their investment in service response.

Stay steady and continue to be ready. You are the answer and the solution. We believe in you.

_________________________________

Posted: January 2, 2022

Come train with K38 and discover what your community is doing to modernize standards, safety and reduce liability!

Copyright © 2022 K38 All rights reserved.

All materials on the Companies websites are the property of K38 and may not be copied, reproduced, sold, or distributed without the express permission of the copyright holder. Liberal use of K38 fact sheets and news releases is allowable with attribution.

To Cite the K38 Website for Reference: Please use the following:

"Reproduced from K38's website, © K38 (year), title and date of the post"

K38 does not grant permission for its content to be displayed on other Web sites, training manuals, unsolicited programs, media, training materials or standards development without expressed written permission.

Caution: Visit page (site) terms and conditions. Please take a qualified Rescue Water Craft training course and maintain proper records and respect all the PWC, RWC, PPE, and OEM manufacturer warning labels and cautions and country of origin regulations. The opinions and information in this post is subject to change as industry alerts, methods or notices are administered through laws, rules, cautions, regulations, or industry standards and will not be reflected in the original post date. Use at your own discretion, risk and caution.

K38 Content Creator of Rescue Water Craft and Personal Water Craft boating international education, jobsite safety and standards: Shawn is the world’s foremost authority and leading subject matter expert. She cares most about her community and the culture surrounding the safety of event service providers, Public Safety Agencies, Military and Rescue Water Craft operators. Dedicated towards protecting their reputation, distributing safety information and continuing to train these amazing individuals to the highest standards of care and competency