BECOME THE STRENGTH

Identify Your Weak Operators. Identify your role as team leader or administrator.

Strength and Weakness are reciprocal. Insert either word and we still discover the same framework of concern.

How much foundational knowledge do you possess to manage a Marine Unit?

What is an Marine Unit Administrator? What is a Coxswain? They are the Operator. They are the Captain. They are in charge of the Crew. They are in charge of the ship (Rescue Water Craft). It is important to identify your weak Coswains for a variety of reasons:

1. Reduction of liability through competence

2. Teaming (building a cohesive unit)

3. Safety at Sea

4. Operational Integrity

5. Mentoring

6. Operational Acumen

It is the precision of opposites we identify. We can easily state this is the same 6 criterion needs for a strong operator or crew!

LACK OF EFFECTIVE MANAGEMENT

When you can identify the weakness in your Operators you have a distinct advantage to identify the complimentary strengths in your team. This is something that needs to be conducted periodically.

How can you make an assessment?

1. Review the condition of the Rescue Water Craft(s)

2. Review the condition of the trailering and Transport equipment

3. Quiz the Operators

4. Skillset assess monthly the technical ability of your team

5. Rate the level of competency and assign the rating in the database

6. Describe the shortcomings and capabilities, make improvement on both!

7. Assign degrees of performance related to service work

If you have an Operator that is identified as problematic in techincal skills, but is high in managing equipment, perhaps a reassignment is necessary? Where are their strengths? What are they comfortable doing? What are the uncomfortable doing?

Provide an honest counseling session regarding performance, executive and completion of all tasks. Ask them if they would be willing to take on another level and manage that specific area of the program. Correlate that with documentation that will verify their factual performance and related success or defaults.

It is important that an administrator oversees and inspects the performance of the team, leaders and program guidelines.

You may need an outside program assessor to partner with who is unbiased but willing to check deficiencies that could lead to a lawsuit, injury, death or program destruction. There is nothing wrong with this, but everything goes wrong when it's not in place and considered important.

K38 Jet Ski Training

STRENGTH

Strength is a needed ingredient in program management and sustainability, but how do we measure strength?

Is id conducted by setting a program and essentially abandoning it year after year because its always been that way or do we determine to investigate the program failures and success?

That begins with the personnel in charge. Whether administrators, operators, crew or mechanics the teaming aspect is critical for future safety as well as present safety and program sustainability.

Make a commitment right now to review your Rescue Water Craft program.

Interview your team.

Ask them what they think is working well and what areas they would like to see changes.

Be courageous and represent integrity, as you may be saving one of your team members reputation or your own.

Care About Your Team

EFFECTIVE LEADERSHIP CARES ABOUT RESULTS

Conduct periodic program reviews. Inspect equipment. Look at mishap or injury reports. Get the entire team together and ask them to share with you their concerns. Do they have adequate budget? Do they have the right equipment? Is the service of the boats adequate? Do they believe their skills are competent?

Review other mishaps. Can you see your team in the video or storyline?

...Otherwise the door is open for a mishap.

Don't wait until you have to learn from a lesson.

Take the lessons now and make a plan. A solid plan.

People do not have to get hurt, Rescue Water Craft do not have to be damaged to learn a lessonM, nor reputations damaged.

Backing up and slowing down your program flow can save your department and your staff intense grief and discouragement.

Review your mishaps. The story is in the actions and the subsequent behaviors can be alerted.

Ask us how we know?

Good luck, we wish you a safe and noble program that you are proud of and your people are operating safely!

_______________________________

Posted: 10.27.2018

Have any questions? Join the Rescue Water Craft Association

and discover what your community is doing to modernize standards, safety and reduce liability!

Join the Rescue Water Craft Association

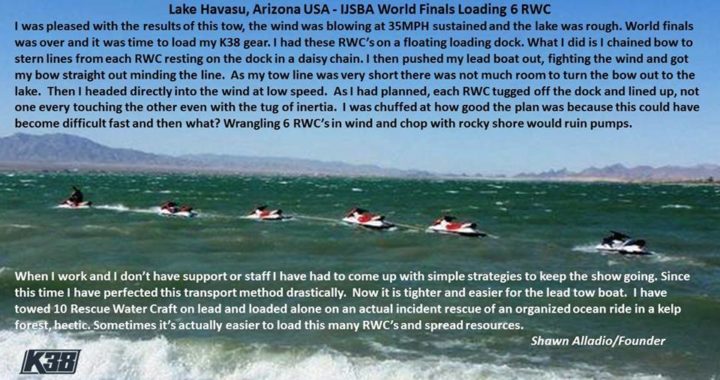

Content Creator: Shawn Alladio cares most about her community and the culture surrounding the safety of event service providers and Rescue Water Craft operators, working hard and dedicated towards protecting their reputation, distributing safety information and continuing to train these amazing individuals to the highest standards of care.

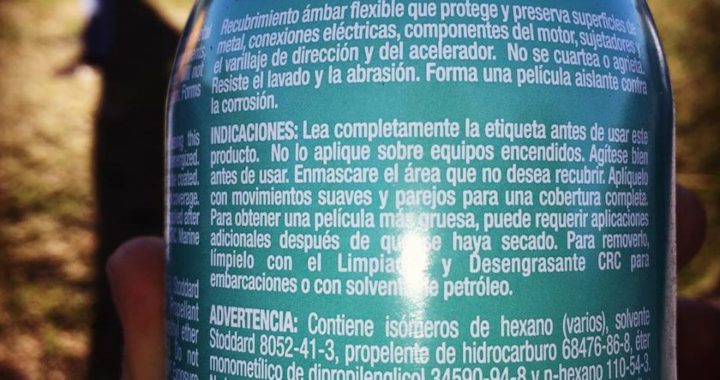

Use at your own risk. Please take a qualified Rescue Water Craft training course and maintain proper records and respect all the PWC, RWC, PPE, and gear OEM manufacturer warning labels and cautions.