Unfortunately Rescue Boards (TAD-Towable Accessory Device) do more damage to our Rescue Water Craft astern due to vessel designs changing but the Rescue Boards designs are not adapting to the newer models. Do Rescue Boards work? Absolutely.

However, the use of these (TAD) Towable Accessory Devices have assisted in the recovery of many persons in distress and we are thankful for their utility. Let’s take a look at considerations of repair and contact points.

Inflatable type designed rescue boards/sleds are not approved for Rescue Water Craft (RWC) safety use due to stability and connectivity. This discussion refers to fixed core rescue boards that cannot be deflated.

It takes a lot of effort to maintain your Rescue Water Craft and Rescue Board. This requires of Public Safety Agencies to have effective training and proper inspection lists to note when Rescue Boards or RWC’s need to be removed from service due to safety maintenance or repairs.

Some models of Personal Water Craft (PWC) interface to the various Rescue Boards or Towable Accessory Devices (TAD) do not interface well with the variety of Rescue Water Craft (RWC) hulls from year of production, makes and models.

Please refer to the Rescue Water Craft Association recommended RWC’s for 2018:

Approved 2018 Rescue Water Craft

It is not an easy interface for sure! Make sure you are watching the attachment points from each use and inspect your hull for wear through the top deck. This requires your RWC Operators to understand what to look for, why it is important and how to inspect and maintain their equipment before a mishap occurs from negligence.

This is especially true for NanoXcel hulls in comparison to fiberglass/gelcoat hulls. These lighter hulls tend to have more flex and the newer models have a concave top deck astern. This is also true for some Sea Doo models.

Will this cause harm to your Rescue Water Craft? What should you be concerned about?

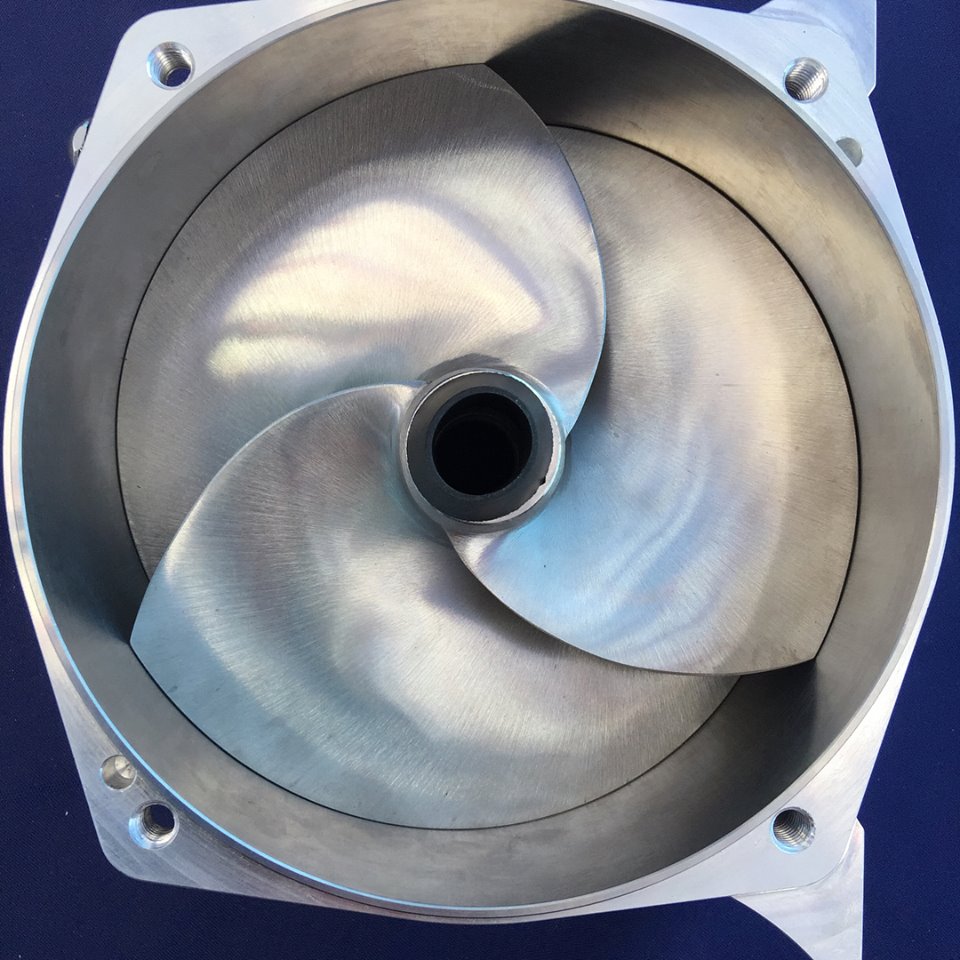

The center load bearing pressure point and the pivot from port to starboard along with how the Rescue Board is designed oftentimes do not have a complimentary fit. Problems may occur from compression indentations against the Rescue Board. Remember, we are not permitted to drill only holes through the RWC hull and we cannot add any metal fittings on the top deck due to safety risk and liability.

Also take note of any entrapment from extension on port/starboard connector points of the Rescue Board, catch points and flexion caused by poor handle placement. These all lead up to contributing factors of friction and Rescue Board contact points to the RWC.

Think one word exclusively: PHYSICS

This means the pressure points from a rescue board are going to be pressed downward at the port/starboard sides and can wear completely through the top deck. This can result in a wear hole through the top deck surface

Bondline Molding damage and damage to contact point of the TAD Point of Contact

Remember: These are recreational Power Water Craft. They are not designed for Search and Rescue or Patrol work. They are designed for recreational activity use. (With the exception of the AlumaSki, Sea Doo SAR and RescueRunner which are occupational manufactured craft).

When you employ the use of a Rescue Board it will require of your agency effective ‘use, inspection and care‘ guidelines for liability and for safety underway. Failure to do so can result in loss of the Rescue Board, damage that cannot be repaired and budgetary needs for RWC maintenance and care. This can also lead up to agency liability issues.

Is this in your annual budget? Do you have maintenance repair items in stock ready to go?

K38 can help your agency set up your RWC program through professional consultation.

Friction points caused by the forces of action and unequal distribution of load, contact, drag or movement against he rescue board and the bond line or top stern deck. Make sure inspections are thorough and replacement parts a readily available in your cache load maintenance gear.

Rescue Board

You may need to alter the material on the stern deck to raise up the void between the two substrates. Refer to your warranty first before you proceed on any modifications and adhere to the guidelines and rules of the warranty.

1. Rescue boards can also pull off or damage the rail bond line or molding exposing the rivets. This can result in a safety hazard. Remove the RWC from service immediately if this happens.

2. Friction and impact can affect or damage the stern top deck or removable stern compartment covers on some models of RWC.

3. Re-boarding steps can be damaged or damage the underside of a Rescue board or cause a slight shock loading effect if the step makes contact on the underside of the rescue board and slides forward or back, this can result in issues with the center load bearing connector point.

4. Rescue Board friction pads or covers can splinter, break of fracture. They can even be ripped off the Rescue Board.

There are so many variables that come into play with physics and the actual weight load on the Rescue Board. Primarily it is the connective interface between the RWC and the Rescue Board that is most important.

Is your rigging causing harm or creating a solution? What are you willing to give up to gain?

There is no defining interface for rescue board use. It depends upon the make, model and year of production of RWC you have.

One thing is for sure, take some time to study the contact points, friction and how the Rescue Board is hooked up to the RWC to try to reduce the impending damage your RWC will suffer.

Shawn Alladio – 2018

Shawn cares most about her community and the culture surrounding the safety of event service providers and Rescue Water Craft operators, working hard and dedicated towards protecting their reputation, distributing safety information and continuing to train these amazing individuals to the highest standards of care.

Use at your own risk. Please take a qualified Rescue Water Craft training course and maintain proper records and respect all the PWC, RWC, PPE, and gear OEM manufacturer warning labels and cautions.

Become a member today of the Rescue Water Craft Association: JOIN THE RWCA