FLOW

Jet pump cavitation is oftentimes confused with the effects of ventilation regarding Personal Water Craft jet pump efficiency. For occupational operators this is a topic of interest for RWC use. We are looking at several aspects of jet pump security:

1. Aerated water conditions are Rescue Water Craft would operate in such as a surf zone or whitewater in a river

2. Damage to the jet pump unit and its components

Our Rescue Water Craft cavitation occurs when the results of extreme reduction in jet pump pressure on the back side of the impeller blades. This creates a loss of water jet pump pressure.

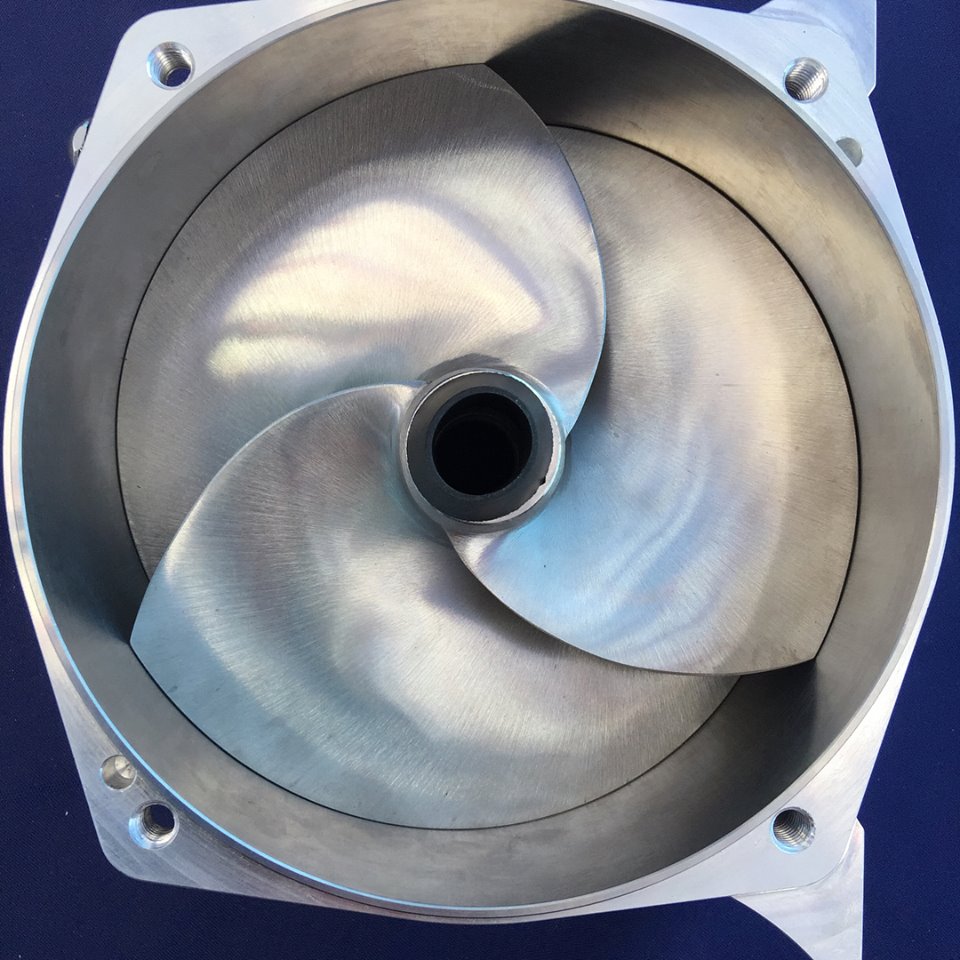

We enjoy two types of constructive materials for impellers, aluminum and stainless steel

PWC Water Intake Screen missing bolt

Rescue Water Craft Cavitation

It is an interesting process that we cannot see while operating our Rescue Water Craft. We can feel the hesitation of the craft, loading up or stalling of the RWC as throttle modulation is applied at the helm. This is most apparent in white water operating conditions. Or if there is debris that is hung up on the water intake screen or beginning to ‘wrap’ around the driveline.

Water begins to boil at 212 degrees Farenheit. If we reduce the atmospheric pressure low enough, water can also boil at room temperature. These boils can effect jet pump efficiency underway.

As the Rescue Water Craft impeller begins turning through the water drawn into the jet pump at an ever-increasing rate of speed, the pressure on the back side of the blades is reduced, and if that pressure is reduced low enough, the water will begin to boil and form water vapor on the blades. This usually occurs near the outer or leading edge of the blade. There can also be damage to the jet pump guide veins on the backside of the impeller.

Inspect your PWC Water Jet Pump for Debris

FLOW DON'T BLOW

Water vapor bubbles will migrate closer to the center of the RWC impeller blade within the Jet Pump. This is where the jet pump pressure is higher, and the boiling stops. The vapor bubbles will begin to implode against the impeller blade's surface.

This resulting energy release can be so strong that it can begin a process of chipping away at the impeller blade surface, leaving what is called a cavitation burn.

Cavitation can have a lot of different causes. Impeller nicks, dents or different types of damage to the leading edge of any of the impeller blades are often the highest contributing factor. If your Rescue Water Craft impeller no longer cuts through the water smoothly from the water drawn through the water jet, it will cause disturbances in the water flow, and this can result in the effects experienced from cavitation.

Ventilation can occur from the bottom hull of the Rescue Water Craft. At each training course or rescue episode we pre and post-inspect the bottom of the hull for any nicks in the gelcoat or substrate surface.

One of our inspection requirements is to check out the water intake screen, the pump tunnel, ride plate, impeller (both lead and trailer blade edges), pump guide veins to ensure there are no cracks, chips, breaks or scores. We also inspect the pump liner and are sure to fresh water flush after each use.

Typically the keel leading up to the dead rise of the bow is a key area for gelcoat damage from repeated groundings. Chines can catch the edge and fleck off small areas of gelcoat. Ventilation can be suspected to affect the jet pump unit if that area has any surface damage.

Inspect your PWC Water Jet Pump Intake Screen for Debris

TRACTION IS SAFETY

Repeated groundings can change the blueprint of the hull bottom. It can cause a grinding away of the centerline of the keel. Not all agencies have the luxury of using boat ramps and trailers. Some must ground their RWC which results in the keel becoming misshaped over time.

Another problem we experience from ventilation is with the use of a Towable Aquatic Device (TAD) or what we commonly refer to in generic term as a ‘Rescue Board’. The more weight applied to the top of the rescue board forward surface, the more dead-rise against the bow will cause increased upward lift.

This is most noticeable when speeds increase or in rough water operations.

Our safety lies within our operational knowledge base. When we understand our pump efficiency and safety we can inspect, maintain and prevent further damages. It also helps us to determine when we have lost a pump or bearings to damage and need to ensure that we don’t stress the engine from overloading rpm.

Get to know your Rescue Water Craft. There is more to know than this story can tell. Start with the jet pump unit and review your owner’s manual for inspection tips. It really is the secret of our forward success!

Content Creator - Shawn Alladio cares most about her community and the culture surrounding the safety of event service providers and Rescue Water Craft operators, working hard and dedicated towards protecting their reputation, distributing safety information and continuing to train these amazing individuals to the highest standards of care.